Steel 1.2758 - MA-Rekord

1.2758 - MA-Rekord steel:

high-alloy and austenitics structure.

What?

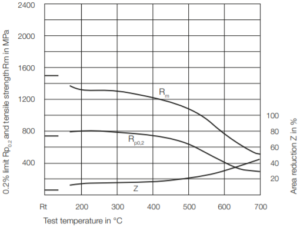

1.2758 – MA-Rekord steel is a high-alloy special hot-work tool steel with austenitic structure. The operational strength of approx. 1350-1550 MPa is achieved through forging and then precipitation hardening at approx. 800 °C or through a special heat treatment.

Material properties

Properties of steel type 1.2758 – MA-Rekord

- Strength trough forging and precipitation hardening or heat treatment.

- Water cooling is not possible.

Application

The most common applications for steel type 1.2758 – MA-Rekord

Extrusion dies for processing hard-to-press non-ferrous metals and steel in the manufacture of wire, rods, pipes, strips and simple profiles.

Delivery condition

As disks forged on all sides with the smallest possible thickness, so that a roughly consistent temperature increase is guaranteed in extrusion press operation, in order to prevent stress cracks due to the limited thermal conductivity.

Tensile strength Rm = 1350 – 1550 MPa

Physical properties of 1.2758 - MA-Rekord steel

| Temperature in °C | 20-100 | 20-200 | 20-400 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.3 | 11.8 | 12.2 |

Heat treatment

| Preheat before use | Temperature: 400 – 600 °C essential, avoid cooling during press operation |

|---|---|

| Cooling after use | Immediately after the last pressing, slowly from 500 – 600 °C in the furnace |