Steel CS1

CS1 steel:

Good toughness and thermal shock resistance.

What?

CS1 steel is a Cr-Mo-V alloyed hot-work tool steel with higher C content compared to TQ1. It is characterised by particularly high strength, hightemperature strength with simultaneously very high toughness and thermal shock resistance and is only manufactured in remelted version according to the ESU process.

Material properties

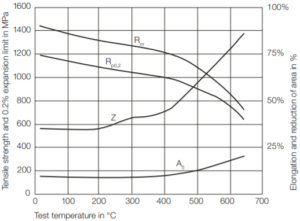

- Hightemperature strength.

- Hightemperature toughness .

- Thermal shock resistance.

Application

CS1 is particularly suitable for loads above the limit of TQ1:

- Extrusion presses: For specific pressures > 1000 MPa, heavy duty press stems, press disks and inner liners.

- Drop forging.

- Hot forming.

Physical properties of CS1

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.8 | 12.5 | 13.2 | 13.4 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 28.8 | 30.0 | 29.4 | |

| Temperature in °C | 20 | |||

| Density in g/cm3 | 7.79 | |||

| Temperature in °C | 20 | |||

| E module in GPa | 213 |

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C, 4 – 6 hrs. |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 230 HB | |

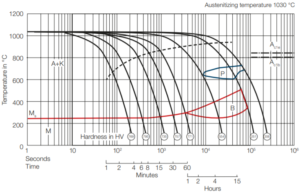

| Hardening | Temperature: 1010 – 1040 °C |

| Cooling: air, warm bath of approx. 540 °C, oil/polymer; Interrupt oil or polymer cooling at 230 – 280 °C or vacuum hardening | |

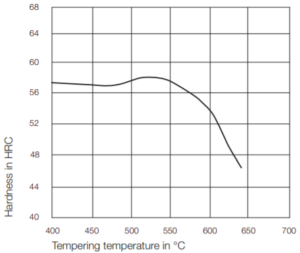

| Tempering | Temperature: 540 – 680 °C |

| Hardness: see tempering graph | |

| Nitriding | Possible |

| Preheat before use | Temperature: 150 – 350 °C |