Steel CR7V-L

CR7V-L steel:

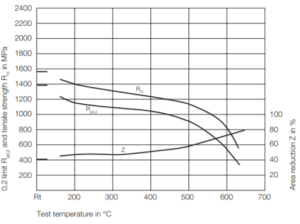

strength, wear resistance and thermal shock resistance.

What?

Steel CR7V-l: high Cr alloyed special steel with Mo and V additives is characterised, with good high-temperature strength, by particularly high wear resistance, both for cold and hot work. Thermal shock resistance is good.

Material properties

- High-temperature strength .

- Wear resistance.

- Thermal shock resistance.

Application

For cold work:

- Punches and shear blade for sheet metal thickness of approx. 6-12 mm.

For hot work:

- Die inserts and mandrels.

- Extrusion dies for steel forming.

- Hot extrusion of copper and copper alloys.

- Hot shear blades and deburring tools.

- Drawing rollers for steel bottle manufacturing.

Physical properties of CR7V-L

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.4 | 11.9 | 12.5 | 13.1 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 26.7 | 29.8 | 30.8 | |

| Temperature in °C | 20 | |||

| Density in g/cm3 | 7.6 |

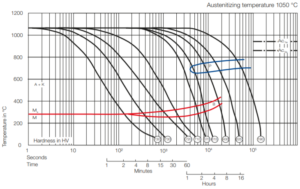

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C, 4 – 6 hrs. |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 240 HB | |

| Hardening | Temperature: 1030 – 1040 °C |

| Cooling: in warm bath of approx. 540 °C, in air or oil/polymer; Interrupt oil or polymer cooling at 250 – 300 °C or vacuum hardening. | |

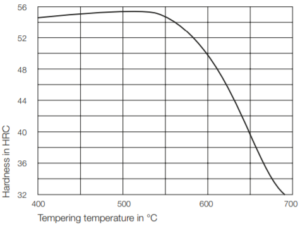

| Tempering | Temperature: 500 – 700 °C |

| Hardness: see tempering graph | |

| Niriding | Possible |

| Preheat before use | Temperature: 150 – 350 °C |