Steel 1.2885 - RPCo

1.2885 - RPCo steel:

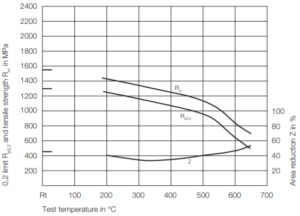

High-temperature strength, tempering resistance .

What?

1.2885 – RPCo steel corresponds to the steel RP with additional Co content. The high-temperature strength, tempering resistance and also high temperature wear resistance are increased.

Material properties

properties of steel type 1.2885 – RPCo

- High-temperature strength.

- Good tempering resistance .

- Good wear resistance.

- Water cooling is possible.

Application

The most common applications for steel type 1.2885 – RPCo are:

- Extrusion press tools such as pressure dies and disks, die holders.

- Extrusion punch heads for copper and copper alloys.

- Impression dies, especially mandrel inserts for copper and copper alloys.

- Piercer heads in steel pipe production.

Physical properties of 1.2885 - RPCo steel

| Temperature in °C | 20-100 | 20-400 | 20-600 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.5 | 12.0 | 12.2 |

| Temperature in °C | 20 | 200 | 400 |

| Thermal conductivity in W/m x K | 30.0 | 32.1 | 34.1 |

| Temperature in °C | 20 | ||

| Density in g/cm3 | 7.9 | ||

| Temperature in °C | 20 | ||

| E module in GPa | 215 |

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C, 4 – 6 hrs. |

|---|---|

| Cooling: soft furnace cooling | |

| Hardheid: max. 240 HB | |

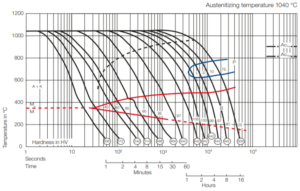

| Hardening | Temperature: 1040 – 1060 °C |

| Cooling Oil or warm bath of approx. 540 °C, Interrupt oil quenching at approx. 200 – 300 °C or vacuum hardening | |

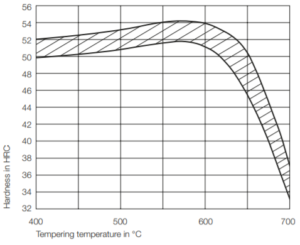

| Tempering | Temperatuur: 560 – 700 °C |

| Hardness: see tempering graph | |

| Nitriding | Possible |

| Preheat before use | Temperature: 150 – 350 °C |