Steel 1.2365 - RP

1.2365 - RP:

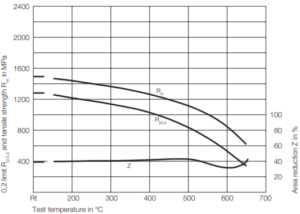

high thermal resistance and tempering resistant

What?

1.2365 – RP steel is a Cr-Mo-V alloyed hot-work tool steel with very high thermal resistance and tempering resistance, water coolable due to good thermal conductivity, so not sensitive to thermal shock. RP is very good for hobbing.

Material properties

Properties of steel type 1.2365 – RP

- High thermal resistance .

- Tempering resistance .

- Not sensitive to thermal shock .

- very good for hobbing ery good for hobbing.

Application

The most common applications for steel type 1.2365 – RP are:

- Extrusion press tools for steel and heavy metal processing, such as pipe extrusion rams, die holders and inner liners

- Compression moulding dies for heavy metal processing

- Tools in forging presses such as die inserts, mandrels, forge jaws and stems for steel processing

- Piercer heads

- Piercers

- Push bench rollers in steel pipe production

Physical properties of 1.2365 - RP steel

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 10.3 | 11.9 | 13.0 | 13.7 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 30.0 | 30.2 | 29.3 | |

| Temperature in °C | 20 | |||

| Density in g/cm3 | 7.85 | |||

| Temperature in °C | 20 | |||

| E module in GPa | 215 |

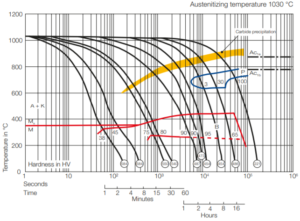

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C, 4 – 6 hrs |

|---|---|

| Cooling: see tempering graph | |

| Hardness: max. 220 HB, for hobbing max. 175 HB | |

| Hardening | Temperature: 1020 – 1050 °C |

| Cooling Polymer, warm bath approx. 540 °C, Interrupt oil or polymer cooling at 230 – 280 °C or vacuum hardening | |

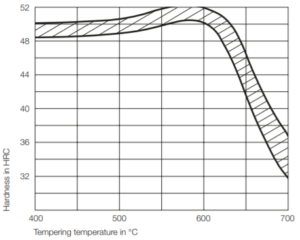

| Tempering | Temperature: 580 – 700 °C |

| Hardness: see termpering graph | |

| Nitriding | Possible |

| Preheat before use | Temperature: 150 – 350 °C |