Steel 1.2343 - USN

1.2343 - USN:

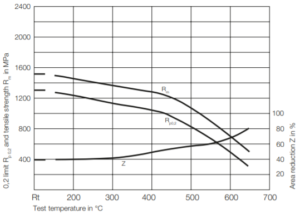

high temperature strength and toughness.

What?

1.2343 – USN steel is a Cr-Mo-V alloyed hot-work tool steel with good high temperature strength characteristics and high-temperature toughness. USN is thermal shock resistant, water coolable, and is characterised by high hardenability.

Material properties

Properties of steel type 1.2343 – USN

- High temperature strength .

- High-temperature toughness.

- Thermal shock resistant .

- Watercooling possible.

- Characterised by high hardenability.

Application

The most common applications for steel type 1.2343 – USN are:

- Extrusion press tools for light metal processing, such as dies, chamber tools, die holders, press mandrels, press stems, container mantles, inner liners.

- Press mandrels and stems for steel and heavy metal processing in extrusion presses.

- Die casting tools such as moulding plates, valves, cores, ejectors, sprue bushings and filling fittings in the processing of light metals and zinc alloys.

- Tools in forging machines such as pressure dies, die inserts, stamps and mandrels for steel, heavy and light metals.

Physical properties of 1.2343 - USN steel

| Temperature in °C | 20-100 | 20-200 | 20-400 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.8 | 12.7 | 12.9 |

| Temperature in °C | 20 | 200 | 400 |

| Thermal conductivity in W/m x K | 26.8 | 27.8 | 27.3 |

| Temperature in °C | 20 | ||

| Density in g/cm3 | 7.74 | ||

| Temperature in °C | 20 | ||

| E module in GPa | 215 |

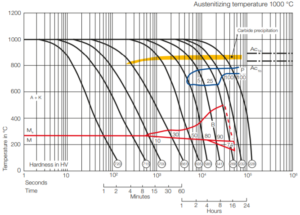

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 220 HB | |

| Hardening | Temperature: 1000 – 1020 °C |

| Cooling Cooling in air, warm bath of approx. 540 °C, Oil/polymer; Interrupt oil or polymer quenching at 230 – 280 °C or vacuum hardening | |

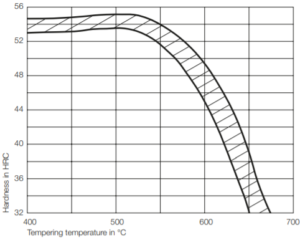

| Tempering | Temperature: 520 – 700 °C |

| Hardness: see tempering curve | |

| Nitriding | Possible |

| Preheat before use | Temperature: 150 – 350 °C |