Steel 1.2767 - N400

1.2767 - N400 steel:

high hardenability and good polishability

What?

1.2767 – N400 steel is characterised by its high Ni content as a tough cold-work tool steel with high hardenability. As well as good polishability and texturing properties, N400 tends towards good through-hardenability.

Material properties

Properties of steel type 1.2767 – N400

- Good toughness.

- High hardenability.

- Good polishability.

- Good through-hardenability.

Application

The most common applications for steel type 1.2767 – N400

- Cutlery stamping dies, shear blades for thick but goods above 12 mm thick.

- Scrap and billet shear blades.

- Embossing and bending tools for heavy cold forming.

- Puller jaws, large lathe punches and similar tools, which demand maximum toughness.

- Shrink rings, tempered as required to a strength of 1300-1600 MPa.

- Plastic moulds.

Physical properties of 1.2767 - N400 steel

| Temperature in °C | 20-100 | 20-400 | 20-600 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 12.3 | 13.1 | 13.7 |

| Temperature in °C | 20 | ||

| Thermal conductivity in W/m x K | 31.0 | ||

| Temperature in °C | 20 | ||

| Density in g/cm3 | 7.82 | ||

| Temperature in °C | 20 | ||

| E module in GPa | 210 |

Heat treatment

| Soft annealing | Temperature: 610 – 650 °C |

|---|---|

| Cooling Slow furnace cooling, 720 °C 6 – 8 hrs,. and slow furnace cooling, annealing 620 – 640 °C 10 – 12 hrs, and slow furnace cooling | |

| Hardness: max. 260 HB | |

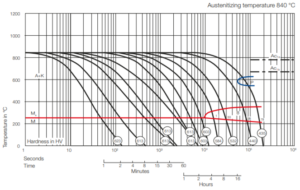

| Hardening | Temperature: 840 – 870 °C |

| Cooling Air, warm bath from 180 – 220 °C or oil, interrupt oil cooling at approx. 150 °C | |

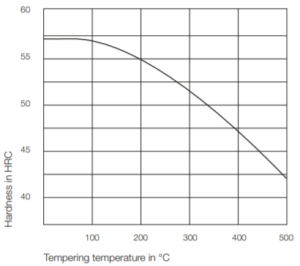

| Tempering | Temperature: 100 – 400 °C |

| Hardness: see tempering curve |