Steel 1.2083 - RF

1.2083 - RF steel:

corrosive- and acid-resistant steel.

What?

1.2083 – RF steel is a high hardenable rust and acid-resistant steel. It is used in the manufacturing of smaller moulds or inserts for the plastics industry in the processing of duroplasts and thermoplasts, in which corrosive side-products can arise. RF is through-hardenable, is low in distortion, has a high wear resistance and compression strength. In tempered condition, RF is very highly polishable.

Material properties

Properties of steel type 1.2083 – RF

- Corrosive- and acid-resistant steel.

- Through-hardenable .

- High wear resistance.

- High compression strength .

- Highly polishable.

Application

The most common applications for steel type 1.2083 – RF

- Inserts and smaller injection moulds.

- Plastic pressure moulds for processing plastics.

Physical properties of 1.2083 - RF steel

| Temperature in °C | 20-100 | 20-400 | 20-600 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 10.6 | 11.7 | 12.2 |

| Temperature in °C | 20 | ||

| Thermal conductivity in W/m x K | 25.3 | ||

| Temperature in °C | 20 | ||

| Density in g/cm3 | 7.7 | ||

| Temperature in °C | 20 | ||

| E module in GPa | 217 |

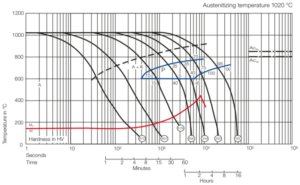

Heat treatment

| Soft annealing | Temperature: 760 – 800 °C, 4 – 6 hrs |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 240 HB | |

| Hardening | Temperature: 1000 – 1030 °C |

| Cooling Interrupt oil cooling at approx. 300 °C; in blast air for thin cross-sections; in warm bath of approx. 200 °C | |

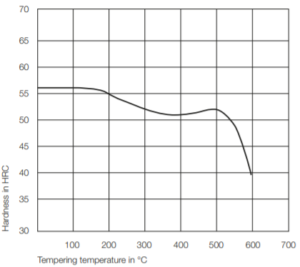

| Tempering | Temperature: 100 – 400 °C |

| Hardness: see tempering curve |