Steel 1.2550 - KL

1.2550 - KL steel:

good toughness and cutting performance.

What?

1.2550 – KL steel is an oil-hardenable steel with very good toughness and relatively good cutting performance. The hardenability capacity is moderate for large cross-sections.

Material properties

Properties of steel type 1.2550 – KL

- Toughness.

- Good cutting performance.

- Hardenability capacity is moderate for large cross-sections.

Application

The most common applications for steel type 1.2550 – KL

- Cutting and punching tools for sheet metal thickness of approx. 6-12 mm.

- Cold punches.

- Deburring tools.

- Profile shear blades.

- Splicers.

- Woodworking tools.

- Small stamping tools.

- Ejectors and similar tools.

- Cutting tools for soft, medium-temperature cutting material (gently preheat tools).

Physical properties 1.2550 - KL steel

| Temperature in °C | 20-100 | 20-200 | 20-400 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.8 | 13.5 | 14.3 |

| Temperature in °C | 20 | ||

| Thermal conductivity in W/m x K | 31.9 | ||

| Temperature in °C | 20 | ||

| Density in g/cm3 | 7.85 | ||

| Temperature in °C | 20 | ||

| E module in GPa | 210 |

Heat treatment

| Soft annealing | Temperature: 750 – 780 °C, 4 – 6 hrs |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 225 HB | |

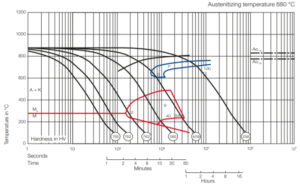

| Hardening | Temperature: 870 – 900 °C |

| Cooling Interrupt oil cooling at approx. 150 °C | |

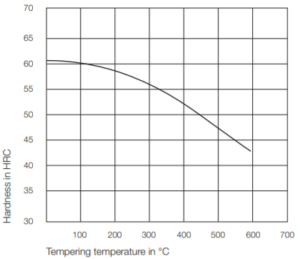

| Tempering | Temperature for hot work 550 – 600 °C |

| Hardness: see tempering curve |