Steel 1.2379 - CH16V

1.2379 - CH16V steel:

dimensional stability and wear resistance.

What?

1.2379 – CH16V steel is a high chrome alloy ledeburitic steel with Mo and V additives. These additives increase cutting stability, hardenability and the through-hardenability. Dimensional stability is good. The ledeburitic structure ensures high wear resistance. CH16V can be nitrided after special heat treatment.

Material properties

Properties of steel type 1.2379 – CH16V

- Dimensional stability .

- Hardenability.

- Wear resistance.

- Nitrided after special heat treatment.

Application

The most common applications for steel type 1.2379 – CH16V

- High performance cutting and punching tools.

- Cold extrusion tools.

- Master hobs.

- Thread rolling tools.

- Flanging and straightening rolls.

- Form rollers for continuous profile and pipe manufacturing from steel strips.

- Woodworking tools.

- Cutting tools for the paper and plastics industry.

- Small plastic moulds or inserts for processing plastics with abrasive fillers.

Physical properties of 1.2379 - CH16V steel

| Temperature in °C | 20-100 | 20-200 | 20-400 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.0 | 12.2 | 12.8 |

| Temperature in °C | 20 | ||

| Thermal conductivity in W/m x K | 20.5 | ||

| Temperature in °C | 20 | ||

| Density in g/cm3 | 7.67 | ||

| Temperature in °C | 20 | ||

| E module in GPa | 215 |

Heat treatment

| Soft annealing | Temperatuure 820 – 850 °C, 4 – 6 hrs |

|---|---|

| Cooling: soft furnace cooling | |

| Hardness: max. 250 HB | |

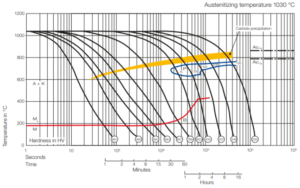

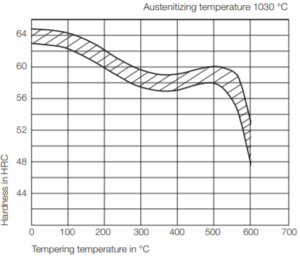

| Hardening | Temperature: 1010 – 1050 °C |

| Cooling Vacuum hardening, oil, polymer, air or warm bath of 350 – 450 °C | |

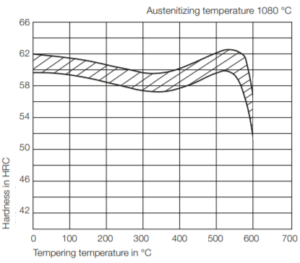

| Tempering | Hardness: Hardness see tempering curve, the higher tempering temperature is preferred for the desired hardness |

Special heat treatment for nitriding

| Hardening | Temperatuure: 1060 – 1080 °C |

| Cooling Vacuum hardening, oil, polymer, warm bath of 350 – 450 °C | |

| Tempering 520 – 580 °C Triple tempering is essential | |

| Nitriding/td> | approx. 540 °C after special heat treatment |