Steel HTR

HTR steel

Thermal shock resistance, high thermal conductivity and high-temperature strength

What?

HTR is a hot work tool steel with very good thermal shock resistance, high thermal conductivity and high-temperature strength. HTR is manufactured exclusively according to the ESU process.

Material properties

- Thermal shock resistance.

- Thermal conductivity.

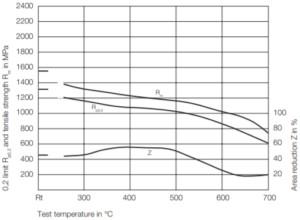

- High temperature strength.

Application

Areas of use with high thermal loads:

- Pressure die-casting (max. 42 HRC).

- Gravity die-casting.

- Extrusion presses.

- Hot/ warm forming.

- Inner liners in heavy-metal extrusion presses.

Delivery condition

Annealed max. 230 HB.

Physical properties

| Temperature in °C | 20-100 | 20-400 | 20-600 |

|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 12.3 | 13.6 | 13.8 |

| Temperature in °C | 20 | 200 | 400 |

| Thermal conductivity in W/m x K | 35.2 | 34.6 | 33.0 |

| Temperature in °C | 20 | ||

| Density in g/cm3 | 8.0 |

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C, 4 – 6 hrs. |

|---|---|

| Cooling: soft furnace cooling | |

| Hardness: max. 220 HB | |

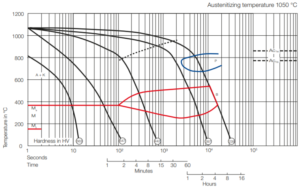

| Hardening | Temperature: 1015 – 1025°C |

| Cooling Oil, polymer, vacuum hardening with nitrogen quenching | |

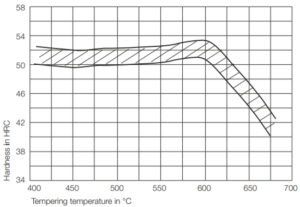

| Tempering | Temperature: 540 – 680 °C |

| Hardness: see tempering graph | |

| Nitriding | Possible |