Steel 1.2889 - HMoD

1.2889 - HMoD steel:

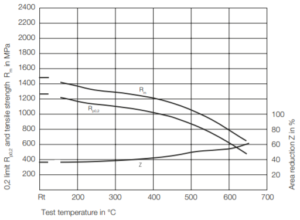

maximum strength and tempering resistance

What?

Because of its composition, steel type 1.2889 – HMoD is a hot-work tool steel with maximum high-temperature strength and tempering resistance with particular high-temperature wear resistance. HMoD has the same areas of application as the steel HWD and is related in respect of the analysis. HMoD is a molybdenum alloy rather than a tungsten alloy with otherwise comparable analysis. Better toughness behaviour can be achieved as a result.

Material properties

Properties of steel type 1.2889 – HMoD

- Maximum high-temperature strength.

- Good tempering resistance with particular .

- Wear resistance.

Application

The most common applications for steel type 1.2889 – HMoD are:

- Extrusion press dies for brass.

- Die versions for heavy metal processing.

- Die-casting dies for casting heavy metals and relatively thin-walled cast pieces.

- Heavy duty cores in the pouring stream, when casting light metals.

- Impression dies, especially mandrel inserts for hot pressing of heavy metals.

- Small die inserts and warm extrusion dies in steel forming.

Physical properties of 1.2889 - HMoD steel

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.2 | 11.8 | 12.3 | 13.3 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 24.1 | 28.8 | 32.3 |

Heat treatment

| Soft annealing | Temperature: 820 – 840 °C, 4 – 6 hrs. |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 240 HB | |

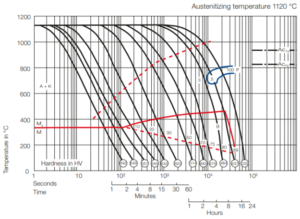

| Hardening | Temperature: 1120 – 1150 °C |

| Cooling Air, warm bath of approx. 540 °C, Oil/polymer; Interrupt oil or polymer cooling at 250 – 300 °C or vacuum hardening | |

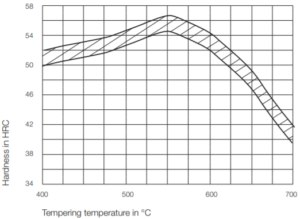

| Tempering | Temperature: 580 – 750 °C |

| Hardness: see tempering graph | |

| Nitriding | Possible |

| Preheat before use | Temperature: 200 – 400 °C |