Steel GSF

GSF steel:

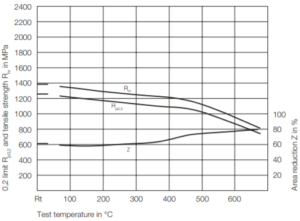

good toughness at high temperature

GSF is a CrNiMoV alloyed high performance steel, which has been specifically developed for dies that are used under the hammer, or for large dies. GSF is the further development of the standard steel 55NiCrMoV7 (1.2714) and is characterised by a better toughness, high-temperature strength and weldability. Because of its good mechanical properties in tempered condition, GSF is the appropriate steel for various tools and heavy duty machine components. GSF is a well-suited alternative to the known tempered steels, especially for large cross-sections or diameters up to 650 mm and strengths above 1000 MPa.

- High performance steel .

- Better toughness.

- Strength by high temperature.

- Can also be used without deposition and filling welding.

- Tool brackets.

- Heavy duty tie rods.

Specially developed forging die steel with good suitability for deposition and filling welding. Because of the lower C content, the risk of crack formation in the weld transition zone is reduced.

Physical properties of GSF

| Temperature in °C | 20-100 | 20-200 | 20-400 | 20-600 |

|---|---|---|---|---|

| Thermal expansion in 10-6m/m x K | 11.8 | 12.0 | 13.0 | 14.0 |

| Temperature in °C | 20 | 200 | 400 | |

| Thermal conductivity in W/m x K | 31 | 34 | 33 | |

| Temperature in °C | 20 | |||

| Density in g/cm3 | 7.76 |

Heat treatment

| Soft annealing | Temperature: 740 – 760 °C, 6 – 8 hrs |

|---|---|

| Cooling: slow furnace cooling | |

| Hardness: max. 230 HB | |

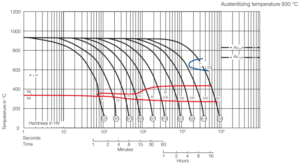

| Hardening | Temperature: 920 – 940 °C |

| Cooling Oil/polymer Cooling must be interrupted at approx. 150 – 180 °C or vacuum hardening. | |

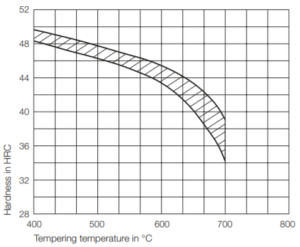

| Tempering | Temperature: 400 – 650 °C |

| Hardness: see tempering graph | |

| Nitriding | Possible |

| Preheat before use | Temperature: 150 – 350 °C |